All-solution processed organic photovoltaics

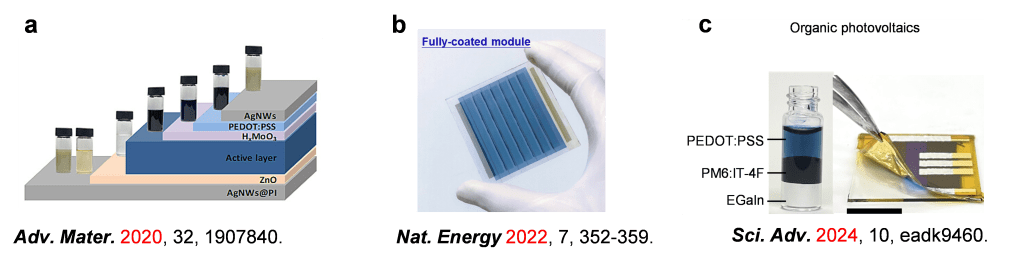

Although the efficiency of the organic solar cells with the rigid ITO glass and vacuum-evaporated metal electrodes has exceeded 20%, the efficiency of devices with an all-solution processed structure suitable for printing is still at a low stage (Efficiency is less than 10%). We designed a stable all-solution processed device structure (from the bottom substrate to the top electrode, as shown in Figure 1a). The introduction of the solution-processed HxMoO3 layer improved hole extraction from the nonfullerene active layer and solved the wetting issues of the PEDOT:PSS on the hydrophobic surface of the active layer. Through this carefully interface engineering, the efficiency of the all-solution processed organic solar cells is closed to 12% for the first time [Advanced Materials, 2020, 32, 1907840, first-author]. And then we developed “triple-layered” all-solution device structure for organic optoelectonics with sparyed liquid metals electodes. The optimized solution-processed liquid metals top electrode can improve the device stability and achieve self-powered health-mooitoring electronics systems [Sci. Adv. 2024, 10, eadk9460, first-author].

Figure 1. (a) The device structure of the all-solution processed organic solar cells. (b) The pictures of the all-solution processed organic solar cells. (c) All-solution processed organic optoelectonics device structure with triple-layered structure.

Flexible organic photovoltaics

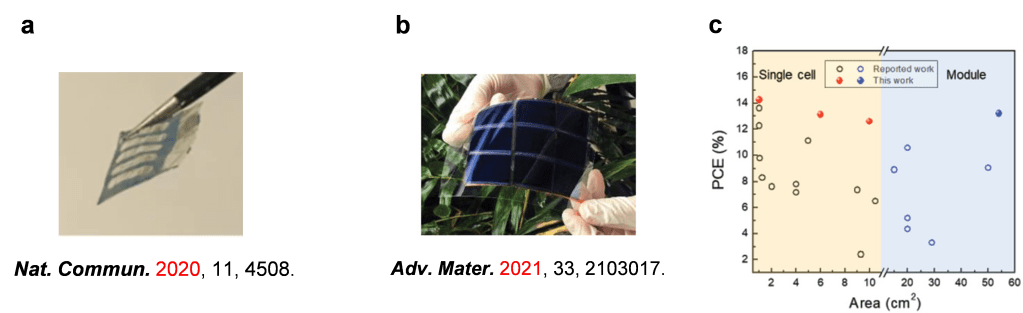

Achieving high power conversion efficiency (PCE) and good mechanical robustness simultaneously is still challenging for ultra-flexible organic solar cells. We fabricated ultra-flexible organic solar cells with a PCE of up to 15% (Figure 2a), which is the highest reported efficiency of the ultra-flexible organic solar cells at the same stage. In this achievement, we developed a metal-chelated polyethyleneimine (PEI-Zn) as the interface layer in the ultra-flexible device structure. The PEI chelated with Zinc ion (Zn2+) reduces its chemical reaction with the high-performance nonfullerene active layer, while maintaining its low work function and excellent mechanical properties. The PEI-Zn offers both higher PCE and better mechanical robustness for ultra-flexible solar cells, comparing with the traditional interface layer ZnO [Nature Communications, 2020, 11, 4508, co-first author].